| Sign In | Join Free | My hardware-wholesale.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My hardware-wholesale.com |

|

Brand Name : YMP

Model Number : YMP-j0633

Place of Origin : Guangdong, China

MOQ : 100

Price : $0.552-0.992 piece

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 3000 pieces per day

Delivery Time : 7 days

Packaging Details : Inner pearl button, outside carton box, or customized

Material : Aluminum

Process : Stamping \Stamping

Surface treatment : Painting\Powder Coating\Plating\Polishing

Product name : aluminum sheet metal fabrication

Service : Customized OEM

Application : Industry

Size : Customized Size

Color : Customized Color

Type : OEM Parts

Drawing format : 3D/CAD/DWG/IGS/STEP/PDF

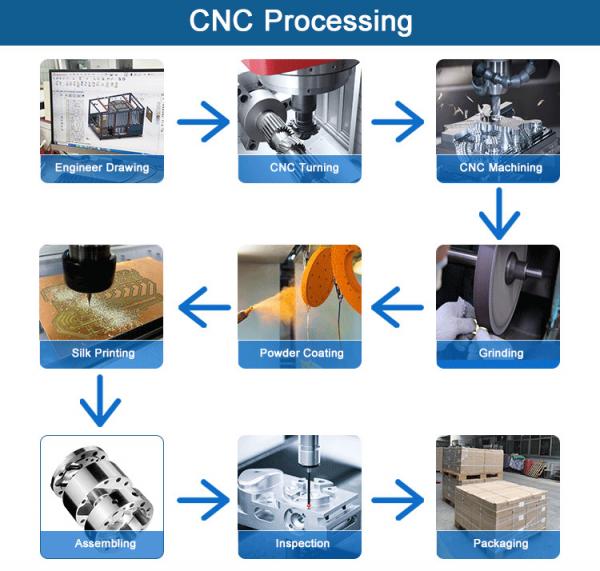

Our main business is CNC machining, plastic injection molding, die casting and stamping parts. The company now has advanced CNC machining center, carving drill, lathe millng machine, wire cutting and other equipment.

With these machines and experienced staff, we are able to deliver repeatable positioningaccuracy within a tolerance of 0.005mm, providing a strong guarantee for precision parts.

We strive to exceed our customers' expectations in all aspects of our product manufacturing process, recognizing our significant responsibilities to our customers, employees, suppliers and society.

We continue to use advanced production equipment, improve efficiency, ensure high and stable quality, and further reduce production costs.

Shenzhen Yixin Precision provides parts design, prototyping, mold design, mold production, mass production and internal assembly services. We work with many customers all over the world and have a deep understanding of the mold industry. Our experience ranges from simple designs to challenging technical parts.

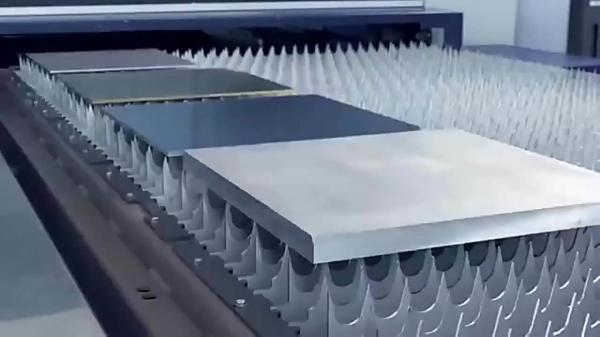

| Product name | Custom Sheet Metal Parts |

| Material | Stainless Steel |

| Process | Laser cutting |

| Size | Customized Size |

| Surface treatment | Polishing, CNC bending automatic welding processing, machine shell processing |

| Color | Customized |

| Application | Industry, Electrical industry |

| Package | Wooden Package |

| Business type | sheet metal fabricator |

| Place of Origin | Shenzhen, China (Mainland) |

The basic process of electroplating is to immerse the parts in the solution of metal salt as cathode and the metal plate as anode and deposit the required plating layer on the parts by the current. A suitable electroplating effect will make your products more fashionable and bring a better market with it. Common electroplating methods include copper plating, nickel plating, silver plating, gold plating, chrome plating, zinc plating, tin plating, vacuum plating, etc.

Most CNC factories only focus on CNC machining but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost but also affect the time to market products.

YMP has rich experience in surface treatment of metal parts, and we will choose a suitable surface treatment process according to different parts' materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sandblasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

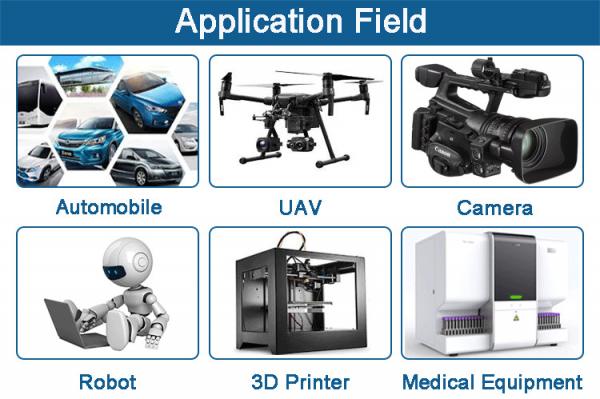

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.

A: We specialize in manufacturing metal stamping parts, sheet metal parts, tube bending fabricating, welded metal parts, and wire forming parts, and are supported with CNC machining and custom hardware fitting.

A: We have our professional manufacturing basement in Shenzhen, Guangdong, Welcome to visit our factory.

A: Yes, we offer value engineering services & design for manufacturability assistance. Prototyping is also available.

A: A variety of secondary assembly services including tapping, fastener installation, plastics assembly, grommets, deburring, labeling, mechanical fastening, and special packing.

A: Drawings or Sample, Material, Finish, and Quantity.

A: Yes, we are flexible with EXW, FOB, CIF, and DDU terms.

|

|

Guangdong OEM Custom High Precision Bracket Connector Aluminum Stainless Steel Sheet Metal Stamping Parts Images |